Bitumen

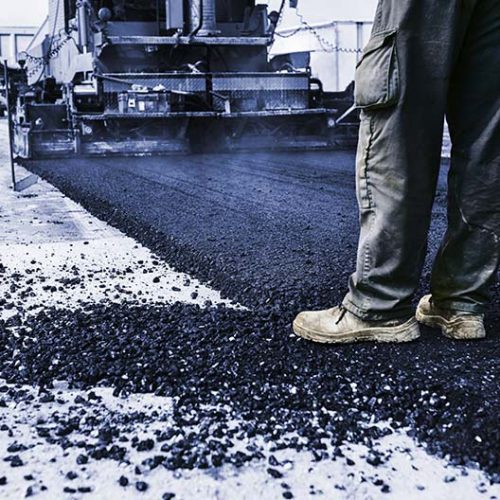

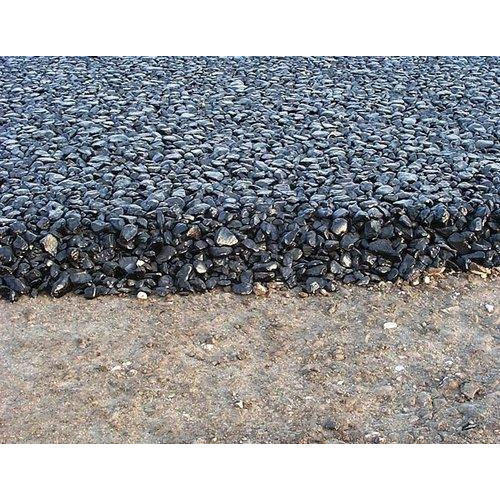

Bitumen is a viscous liquid or semi-solid form of petroleum consisting of hydrocarbons and their derivatives. It is obtained by refinery processes from petroleum or found as a natural deposit. It is usually available in dark colors ranging from brown to black. The main purpose of bitumen in flexible pavements is to strongly bind and hold the other pavement components together and provide a smooth and leveled surface for moving vehicles in road construction. Current world use of bitumen is approximately 100 million tonnes per year. About 85% of all bitumen produced (grade 60/70) is used as a binder in asphalt for road construction. A further 10% is used in roofing applications and remaining 5% is used for sealing and insulating purposes.

The global bitumen market size was $66.10 billion in 2015 and is expected to reach $79.91 billion by 2024. Increasing use in various applications including roadways and rapid urbanization in emerging countries like India (building 40 km roads/day) has resulted in increasing demand for bitumen. India has a road infrastructure of 3.3 million km, the second largest road network in the world, after the US. The government has prioritized the development of roads, allocating more than 10% of total spending from 2014-19 to the road sector.

Bitumen with Penetration Grade

|

Characteristic

|

Grade 60/70

|

Grade 80/100

|

Test Method (ASMT)

|

|---|---|---|---|

|

DUCTILITY @ 25 Deg C in Centimetres

|

100 Min

|

100 Min

|

D-113

|

|

FLASH POINT in Deg C

|

250 Min

|

225 Min

|

D-92

|

|

PENETRATION @ 25 Deg C in 0.1 Millimetres

|

60 – 70

|

80 – 100

|

D-5

|

|

SOFTENING POINT in Deg C

|

49 – 56

|

45 – 52 Min

|

D-36

|

|

SOLUBILITY IN CS2 (WT %)

|

99.5 Min

|

99.5 Min

|

D-4

|

|

SPECIFIC GRAVITY @ 25 Deg C

|

1.01 – 1.06

|

1.01 – 1.05

|

D-70

|

|

LOSS ON HEATING (%WT)

|

0.2 Max

|

0.5 Max

|

D-6

|

|

DROP IN PENETRATION AFTER HEATING in %

|

20 Max

|

20 Max

|

D-5 & D-6

|

|

ORGANIC MATTER INSOLUBLE IN CS2 (WT %)

|

Negative

|

0.2 Max

|

D-4

|

|

SPOT TEST

|

Negative

|

Negative

|

A.A.S.O.T.102

|

Bitumen Penetration Grade 60/70 is commonly used in road making at tropical regions.

Bitumen Penetration Grade 80/100 is a standard penetration grade Bitumen usually used as a Paving Grade Bitumen suitable for road construction and for the production of asphalt pavements with superior properties. This grade of Bitumen is mainly used in the manufacture of hot mix asphalt for bases and wearing courses.

Bitumen with Viscosity Grade As Per IS 73:2006

|

Characteristic

|

VG – 10

|

VG – 20

|

VG – 30

|

VG – 40

|

|---|---|---|---|---|

|

Absolute Viscosity, 60 Deg C, Poises, Min

|

800

|

1600

|

2400

|

3200

|

|

Kinematic Viscosity, 135 Deg C, CST, Min

|

250

|

300

|

350

|

400

|

|

PENETRATION @ 25 Deg C in 0.1 Millimetres

|

60 – 70

|

80 – 100

|

D-5

|

D-113

|

|

Flash Point, C, Min

|

220

|

220

|

220

|

220

|

|

Solubility in Trichloroethylene, %, Min

|

99.0

|

99.0

|

99.0

|

99.0

|

|

Penetration at 25 Deg C

|

80 – 100

|

60 – 80

|

50 – 70

|

40 – 60

|

|

Softening Point, C, Min

|

40

|

45

|

47

|

50

|

|

Tests on Residue from Thin Film Over Test / RTFOT:

|

||||

|

1 } Viscosity Ratio at 60 Deg C, Max

|

4.0

|

4.0

|

4.0

|

4.0

|

|

2 } Ductility at 25 Deg C, Min, after Thin Film Over Test

|

75

|

50

|

40

|

25

|

VG-10 Bitumen is widely used in spraying applications such as surface-dressing and paving in very cold climate in lieu of old 80/100 Penetration grade. It is also used to manufacture Bitumen Emulsion and Modified Bitumen products.

VG-20 Bitumen is used for paving in cold climate & high altitude regions.

VG-30 Bitumen is primarily used to construct extra heavy duty Bitumen pavements that need to endure substantial traffic loads. It can be used in lieu of 60/70 Penetration grade.

VG-40 Bitumen is used in highly stressed areas such as intersections, near toll booths and truck parking lots in lieu of old 30/40 Penetration grade. Due to its higher viscosity, stiffer Bitumen mixes can be produced to improve resistance to shoving and other problems associated with higher temperature and heavy traffic loads.

BITUMEN EMULSION

Slow setting emulsion

Bitumen emulsion, a special type of emulsifier is used to slow the process of water evaporation. These types of emulsifier are relatively stable.

SS-1 : Slow Setting Emulsion – 1

SS-2 : Slow Setting Emulsion – 2

Medium setting emulsion

Bitumen emulsion doesn’t break as when applied on aggregate. The process of evaporation starts when the fine dust of mineral are mixed with the aggregate emulsion mix.

MS : Medium Setting

Rapid setting emulsion

Bitumen emulsion breaks down rapidly as it comes with contact with aggregate helping in fast setting and rapid curing.

RS-1 : Rapid Setting Emulsion – 1

RS-2 : Rapid Setting Emulsion – 2

Akash Overseas Group Range Of Products:

BITUMEN

Bitumen Penetration Grade 60/70

Bitumen Penetration Grade 80/100

Bitumen Viscosity Grade VG-10

Bitumen Viscosity Grade VG-20

Bitumen Viscosity Grade VG-30

Bitumen Viscosity Grade VG-40

BITUMEN EMULSION

RS-1 : Rapid Setting Emulsion – 1

RS-2 : Rapid Setting Emulsion – 2

MS : Medium Setting

SS-1 : Slow Setting Emulsion – 1

SS-2 : Slow Setting Emulsion – 2

Burning Fuel Oil

| HEAVY FUEL OIL | LIGHT FUEL OIL |

|---|---|

| Furnace Oil (FO) | LDO-1 Segments: Hot mix & Construction (Regular) |

| Residual Fuel Oil (RFO) | LDO-2 Segments: Hot mix & Construction (Special) |

| Carbon Black Feed Stock (CBFS) | Boiler Fuel |

| Bio-Diesel Residue | |

| Pitch Oil | |

| MTO |